Supply chain sustainability and management

The company strives to earn the trust of customers through experience, expertise, and business ethics. We work closely with farmers, cooperatives, factories, exporters, companies, businesses, NGOs, and public institutions to promote sustainable production methods. Maintaining a continuous and uninterrupted supply of production resources is the goal of ACBT in building strong business relationships with its raw material suppliers. We participate in various associations that provide long-term, reliable, and secure raw material supplies to ensure our production output remains unaffected. We support supplier diversification, hoping to provide more opportunities to cooperate with different manufacturers and help reduce costs through healthy competition. Supplier selection will be based on individual strengths, product quality, expertise, and support services.

Supply Chain Management

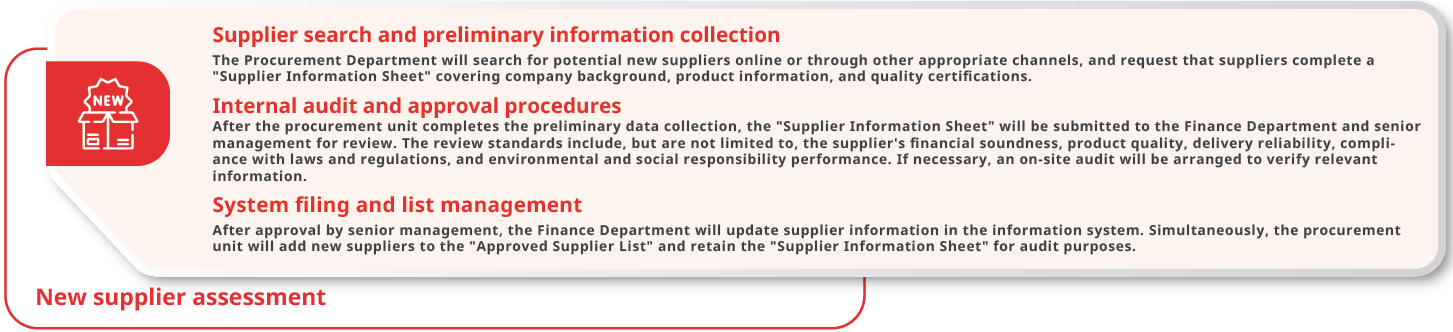

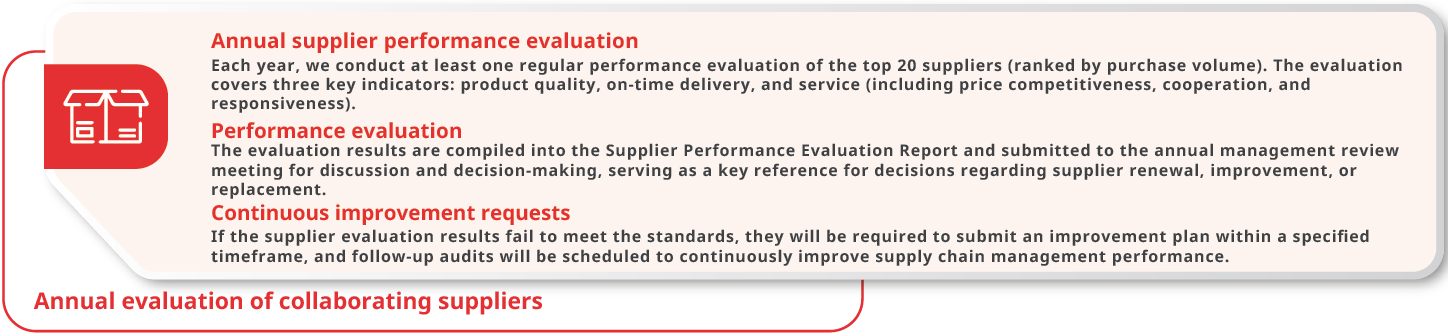

Supplier Management Process

- Supplier performance evaluation:

| Rating & Score Year | Annual evaluation | ||||

|---|---|---|---|---|---|

| A (13~15) | B (10~12) | C (7~9) | D (6 or less) | ||

| 2024 Top 20 suppliers | 20 | 0 | 0 | 0 | |

Local Procurement

- Proportion of Spending on Local Suppliers

| Location | Type | Procurement Amount | Local Procurement Amount | Local Procurement Ratio |

|---|---|---|---|---|

| Malaysia | Raw materials | 97,681 | 31,523 | 32% |

| Packaging materials | 4,230 | 3,210 | 76% | |

| Others | 8,610 | 6,877 | 80% | |

| Total | 110,521 | 41,610 | 38% |

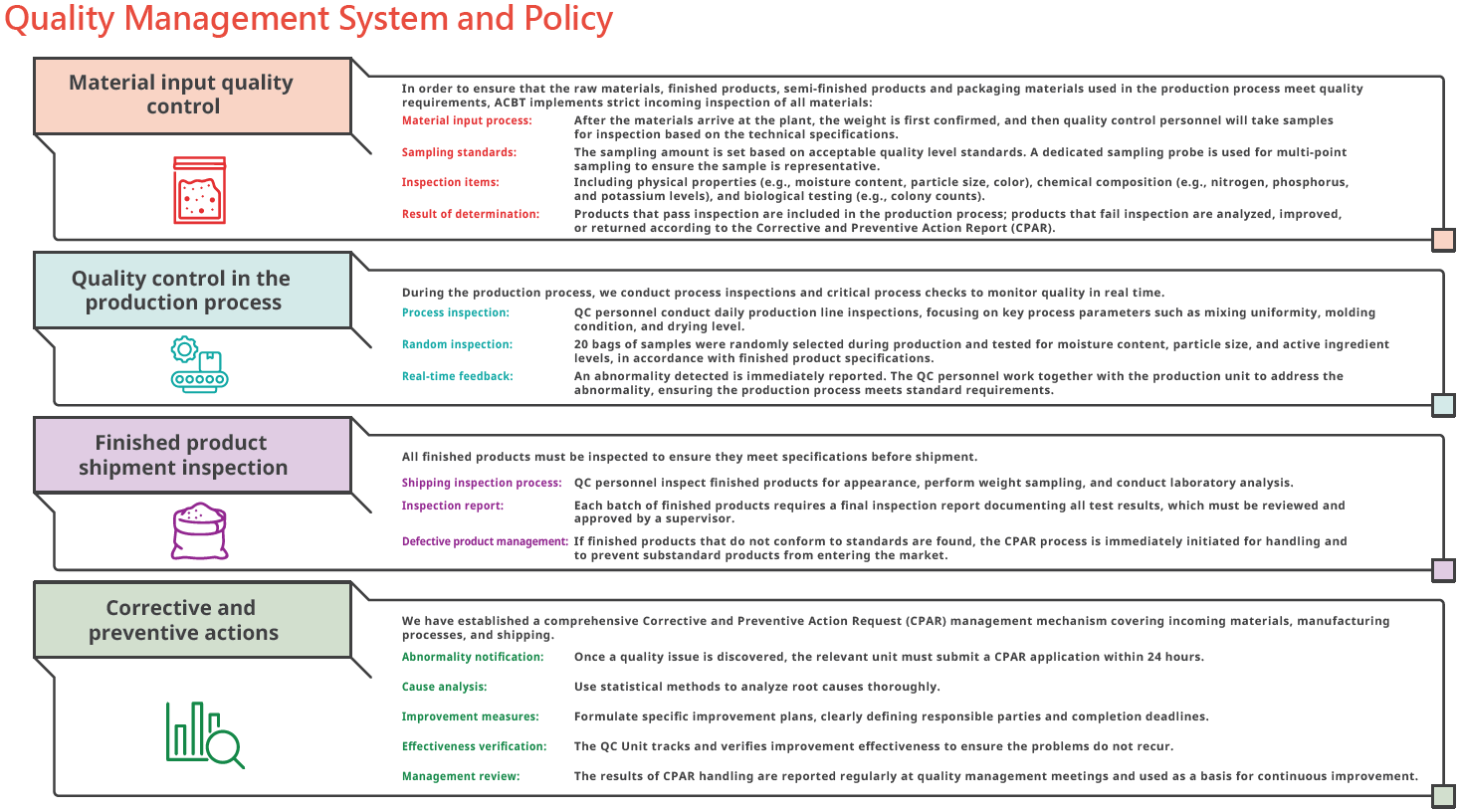

Product Quality Management

Quality Management System and Policy

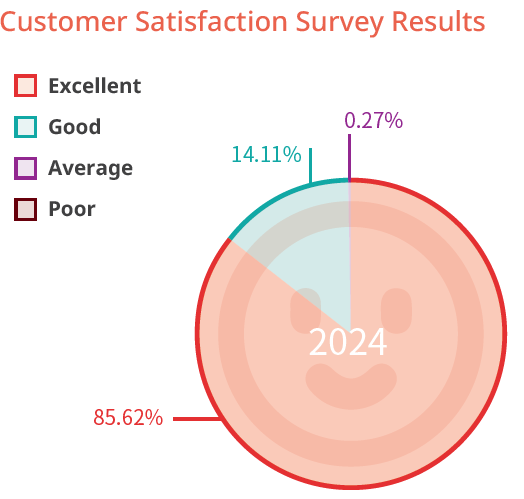

Customer Satisfaction Management

We view "customer satisfaction" as the core foundation of our business and brand trust, and we are dedicated to meeting our customers’ diverse needs with high-quality products and comprehensive services. To systematically understand customer feedback and market expectations, we conduct customer satisfaction surveys annually, covering areas such as product quality, delivery efficiency, technical support, and after-sales service. The survey results will be used as a key foundation for internal improvement plans and resource allocation to continuously optimize customer experience and strengthen customer relationships.

Customer Complaint Handling Mechanism

To effectively address customer complaints and enhance service quality, ACBT has established a comprehensive customer complaint management process. According to the SOP for handling customer complaints, upon receipt of a customer complaint, the QC Department will log the case and create a complaint form for tracking and management. The case requires review and assignment by the general manager to the relevant department for investigation and resolution. The responsible unit shall complete a preliminary response within 48 hours, provide a root cause analysis, and propose specific improvement measures to ensure effective problem resolution. For systematic issues, continuous tracking and preventive improvement will be incorporated into quality management meetings, and regular internal training conducted to enhance response capabilities. All customer complaint data is included in statistical and archival management and serves as a basis for future operational improvements and risk prevention. In response to the primary causes of customer complaints, the Company has implemented several significant improvement measures, including:

Cooling system upgrade: Introduce new cooling equipment to optimize the molding and curing of granular products and reduce the rate of finished product clumping.

Mixing process optimization: Adjust the equipment and stirring parameters to improve raw material mixing uniformity and ensure consistent nutrient distribution.

Education and training strengthening: Regularly organize quality awareness and operational skill training for production and quality staff to improve quality awareness.

From 2023 to 2024, the number of customer complaints decreased from 13 to 10. The above efforts have effectively lowered the product defect rate and increased customer satisfaction, showcasing ACBT’s commitment to continuous quality improvement